Hello everybody! Guess what? M. Cheesemonger and I leave for our Italy/Amalfi coast trip at the end of THIS WEEK! I am just about done packing! I bought a new battery for my camera, so I’ll have two, we’ve got the GoPro packed—oh, and a bathing suit and empty bag. I can’t wait to eat and see EVERYTHING! We even managed to get tickets to see the opera l’Isola Disabitata by Niccolò Jommelli at the Teatro di San Carlo in Napoli. I’ll be on the lookout for evening church concerts wherever we are . . . those are my favorite. Have you got any suggestions for me? Let me know!!!

As for this week! I am VERY pleased to bring you an inside peek at one of my favorite chocolate companies—Dandelion Chocolate in San Francisco! Their single-origin chocolate bars have gained a widespread following all over the world (they’re even going to be at the Cannes Film Festival this year!). Visitors flock to Dandelion’s Mission District café|shop|factory, where they regularly offer free tours of the chocolate making process. However, reservations fill up quickly, and Dandelion is booked for months in advance. If you can’t get into a tour, this blog post might be the next best thing!

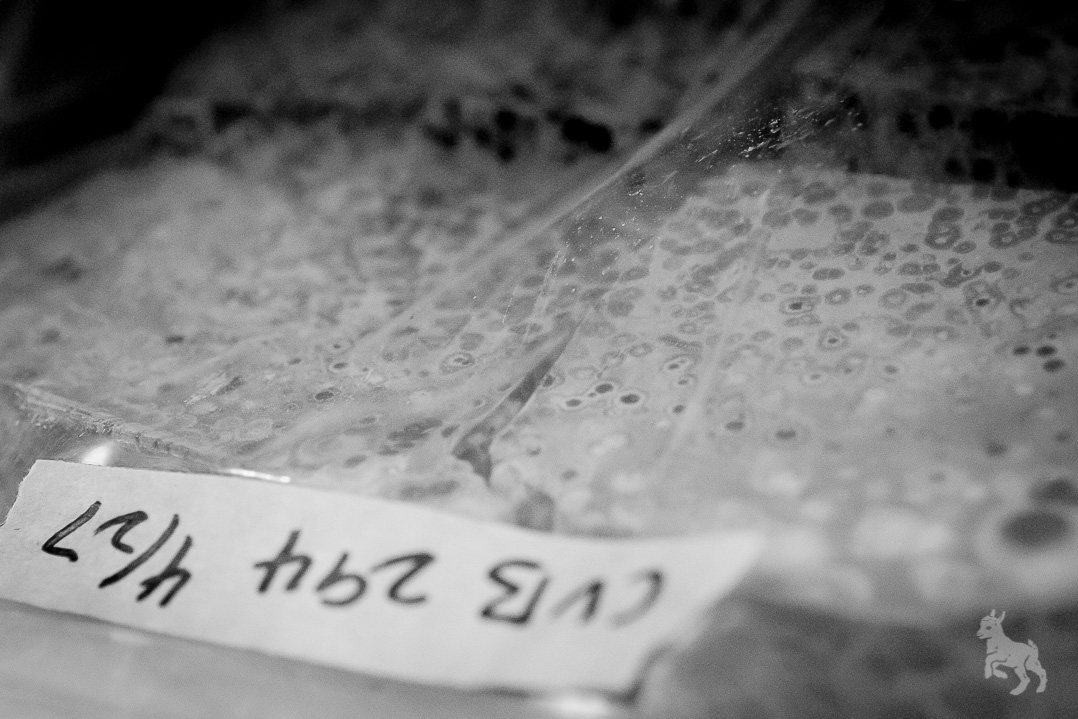

Jennifer, who has been with Dandelion for three years, showed me around. We began our visit in a cool room in the back of the facility, where huge sacks of cocoa beans sat stacked against one wall, and labeled, transparent plastic containers of cocoa beans sat in another. All beans that arrive must first be sorted to discard any foreign objects, as well as check for quality. All of the beans that come to Dandelion must meet strict quality standards, so strict that about 10% are rejected. Terroir is a big factor in what makes Dandelion’s chocolates unique—each chocolate bar is sourced from one region —a different location for each chocolate bar. Because cocoa bean crop quality and quantity can fluctuate in any one location, Dandelion’s offerings can change as well. However, Jennifer assured me that the beans for Ambanja, Madagascar, Dandelion’s most popular bar, are in steady supply. Not only that, contrary to what some of the sensationalist headlines have been saying, the world is not going to run out of chocolate any time soon.

Next, comes roasting. The team at Dandelion constantly tests new sources of cocoa beans—they develop unique roast profiles for each source of bean to bring out that particular bean’s flavor. You can see that at the roaster, a modified coffee roaster now commissioned to roast cocoa beans. Depending on the bean origin, they can roast from nineteen minutes to thirty-five minutes at fairly low temperatures. There’s even a little cheat sheet attached to the roaster so no one gets confused!

After the beans are roasted, the precious inner nibs must be separated from the shells. It’s called winnowing. Dandelion’s own Todd and Gregg conceived of an ingenious machine that rolls the shells off of the nib, and uses gravity to separate the heavier nibs from the lighter shells.

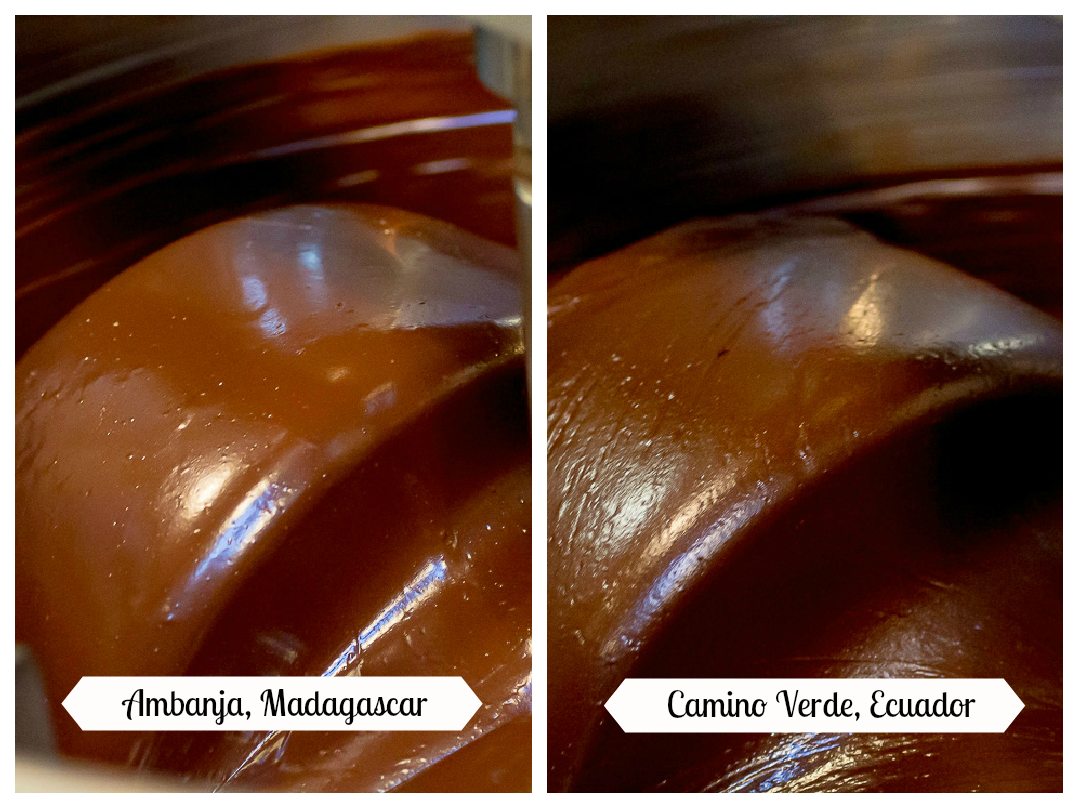

Once the nibs are isolated, they move to the melanger, where heavy stone rollers refine the nibs and added sugar to their desired flavor and consistency. Each bean has its own prescribed time spent in this step (somewhere between two and four days). I could see the differences between two different batches being prepared here. The Ambanja, Madagascar chocolate was a bright reddish color, while a couple of machines over, the Camino Verde, Ecuador chocolate was a rich, velvety brown.

After the chocolate is ground to the right consistency, they are kept in blocks until they are ready to be tempered and turned into bars.

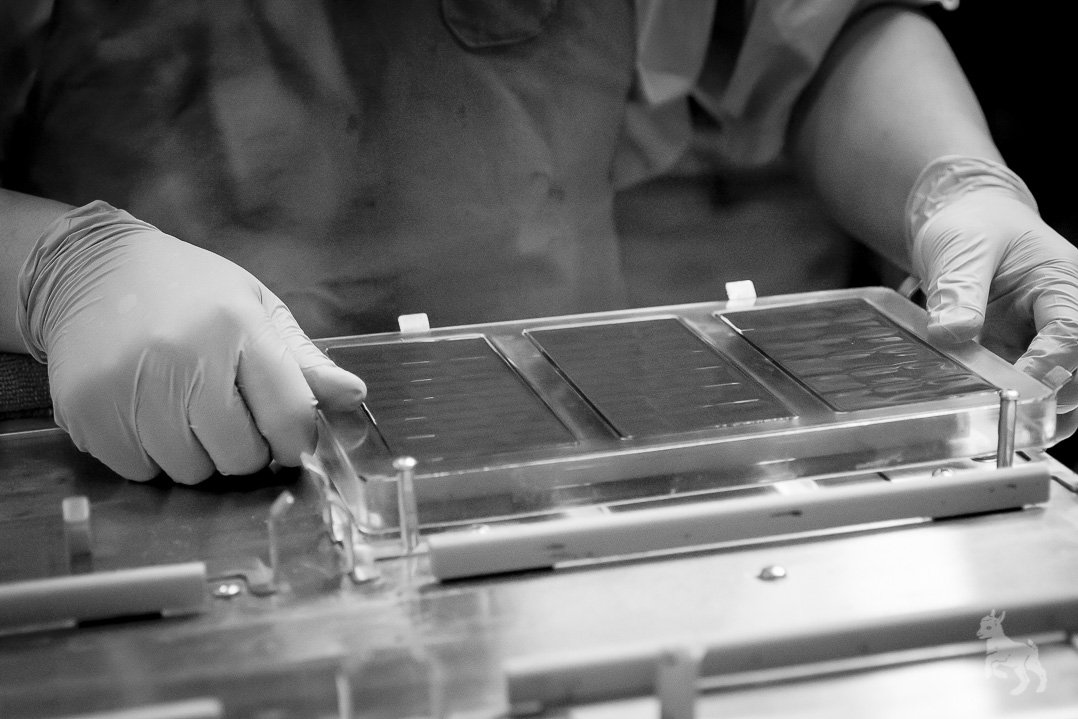

Tempering is the next step, where the chocolate develops that nice snap when broken, as well as shelf stability. The process involves heating and working the chocolate in a precise way to align the fat crystals in the chocolate, which will give it a stable molecular structure. Dandelion has a machine to do this, so they can make 3,000 bars a week.

The bar formation and wrapping are done primarily by hand. A machine doses out the proper amount of chocolate into plastic bar molds, which are then agitated a bit to spread the chocolate evenly. They are cooled for 20 minutes before being removed, and wrapped in gold foil by the two lovely people at the wrapping station. Then, the bars are wrapped in gorgeous Indian paper, and are sold online, in their shop, or sent to retailers around the world.

For the moment, Dandelion sells its chocolate online, in its shop, and in a few select retailers. You might see it in a few new places in the near future, though, because in a couple of weeks, Dandelion will break ground on a brand new facility, also in the Mission district of SF. Their new space will allow production to increase tenfold, and create a more lounge-y setting in which to enjoy their chocolate. With more production, we may also be able to see Dandelion Chocolate on restaurant dessert menus (think of all the sweet possibilities!) I cannot wait to see that!!

Before leaving, I tasted their European drinking chocolate—probably the equivalent of two bars of chocolate in a tiny cup. It’s heavenly, the chocolate version of brocade—thick, opulent, and warm!

After visiting, I really understood how simple Dandelion’s chocolate is. With only two ingredients—cocoa beans and sugar—the unique qualities of each location’s beans shine alone. It’s really quite extraordinary that there can be so much flavor and color variation amongst different beans—for instance, the honeyed San Francisco de Macoris, Dominican Republic, berry notes of Ambanja, Madagascar, and spicy flavors of Mantuano, Ecuador.

Thank you, Dandelion Chocolate, for letting me visit! I can’t wait to see what you do next!

Dandelion Chocolate: 740 Valencia St, San Francisco, CA 94110. (415) 349-0942. Mon – Thu, Sun: 10am – 9pm. Fri, Sat: 10am – 10pm. Call or visit their website for more information about classes and tours.

Follow me on Instagram, Facebook, Pinterest, Twitter, & my mailing list!

Support Miss Cheesemonger by shopping on Amazon! Then get your beef jerky fix at Uncle Andy’s Jerky!